Differences between Homopolymer and Copolymer

Some thermoplastics, besides being available in various flow rates, can also be found with the

homopolymer or

copolymer chain option, where homopolymer is the plastic resulting from the polymerization of a single monomer while the copolymer is that resulting from the polymerization of two or more monomers.

Examples:

The

PP polymerized from propene is a polypropylene homopolymer.

The

PP polymerized from propene and ethylene is a polypropylene copolymer.

ABS is a terpolymer (but can also be called a copolymer) because it is formed by three monomers: acrylonitrile, butadiene and styrene. Therefore, there is no homopolymer ABS, the same thing happens with the other styrene materials with the exception of

PS.

What difference does homopolymer or copolymer make?

I believe the two materials that make the most difference are

polyacetal and polypropylene.

Polypropylene is usually copolymerized with ethylene, which is the polyethylene monomer, so the PP improves some of its characteristics with those found in PE, such as excellent chemical resistance and very good impact resistance.

The polyacetal is copolymerized with ethene oxide or trioxane (a crystalline form of formaldehyde, the monomer of the polyacetal itself), having an improved chemical resistance, higher resistance to creep (under load) in the long term and higher Thermal stability, the latter a very important property since the polyacetal homopolymer can not withstand working at temperatures above 185°F (85°C), whereas in the copolymer this limit rises to 221°F (105°C).

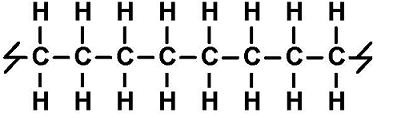

Structure of polyethylene homopolymer with only mers of ethylene (C2H4)

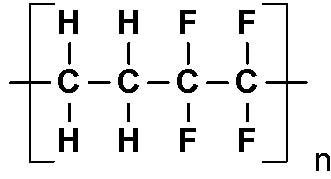

Structure of polyethylene homopolymer with only mers of ethylene (C2H4) Copolymer of ethylene (C2H4) and tetrafluoroethylene (C2F4)

Copolymer of ethylene (C2H4) and tetrafluoroethylene (C2F4)

Bibliography:

HARPER, Charles A.; PETRIE, Edward M. Plastics Materials and Process: A Concise Encyclopedia. Hoboken: John Wiley & Sons, Inc., 2003.

CANEVAROLO JR., Sebastião V. Ciência dos Polímeros: Um texto básico para tecnólogos e engenheiros. 2.ed. São Paulo: Artliber Editora, 2002.

WIEBECK, Hélio; HARADA, Júlio. Plásticos de Engenharia: Tecnologia e Aplicações. São Paulo: Artliber Editora, 2005.

© 2010-2024 - Tudo sobre Plásticos.

All rights reserved.

Home

-

Privacy policy

-

Contact