Polyethylene terephthalate (PET)

Preforms

Preforms

Also called Polyethylene terephthalate, or merely PET, is a thermoplastic polyester, as well as

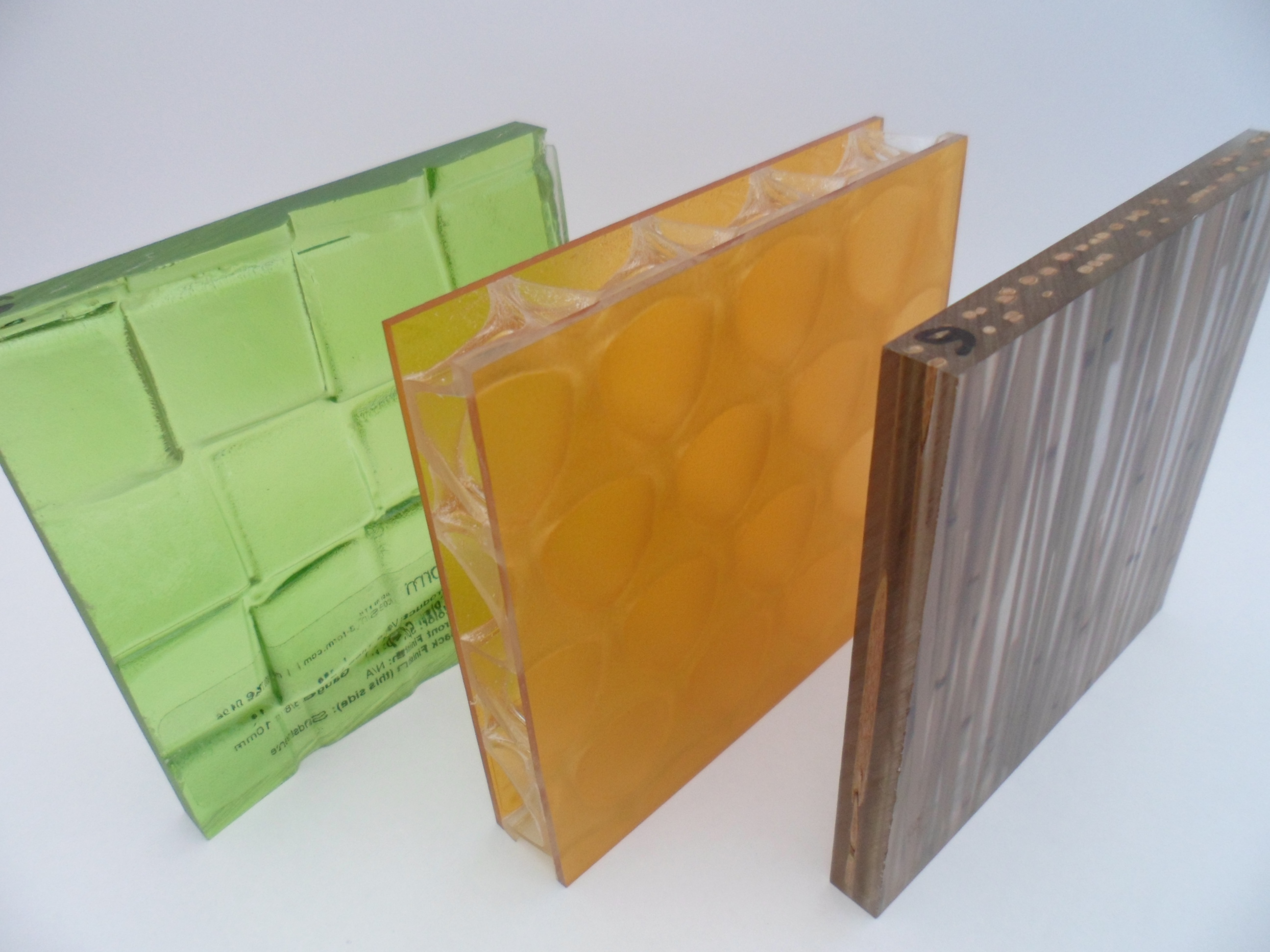

PBT, PCT and LCP. PET resin is mainly used for the production of preforms having 3.15 to 5.9 inches (8 to 15 cm) in length (figure on the side), which are then blown into the form of bottles; Other PET applications include film oriented, fabrics, tubes, banding tapes, plates and broom bristles, where some of these products are made from recycled PET, the so-called "bottle grade PET".

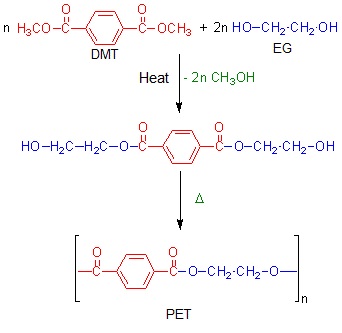

PET can be obtained by reaction between dimethyl terephthalate (DMT),

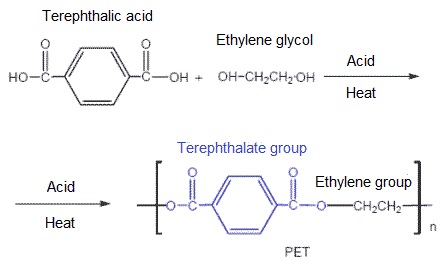

or terephthalic acid (PTA), and ethylene glycol (EG). Therefore, there are two methods of obtaining:

Transesterification of dimethyl terephthalate (DMT) with ethylene glycol (EG) - method used in order to overcome the difficulty of obtaining terephthalic acid of sufficient purity for the process. It is an old method but still used by some companies.

Direct esterification of purified terephthalic acid (PTA) with ethylene glycol (EG) - Is the preferred method of the largest PET resin manufacturers today. In Brazil, both PTA and PET are produced exclusively in the PQS Complex in Ipojuca, Pernambuco.

PET can be processed by injection, extrusion, blowing and thermoforming. Because it is a hygroscopic material, like other polyesters, the PET needs drying for a period between 4 and 6 hours, a time considered long in relation to other thermoplastics. The drying temperature should be high, between 320 and 347°F (160 and 175°C). If this resin is subjected to the transformation process without adequate drying, it will consequently undergo degradation by hydrolysis having molecular weight reduction, loss of intrinsic viscosity and physical properties.

The temperatures for the injection processing are between 475 and 536°F (246°C and 280°C) with mold between 86 and 275°F (30°C and 135°C), while for extrusion these values are between 518 and 538°F (270°C and 281°C) (values calculated from a Series of commercial PET process recommendations). It is recommended that the machine screw be specially designed for PET.

Features:

- Chemically inert

- High impact resistance

- Excellent gas and odor barrier properties

Applications:

Oriented films, fabrics, tubes, bows, plates, tiles, clotheslines, broom bristles, bottles, suitcases

Bibliography:

HARPER, Charles A.; PETRIE, Edward M. Plastics Materials and Process: A Concise Encyclopedia. Hoboken: John Wiley & Sons, Inc., 2003.

WIEBECK, Hélio; HARADA, Júlio. Plásticos de Engenharia: Tecnologia e Aplicações. São Paulo: Artliber Editora, 2005.

© 2010-2025 - Tudo sobre Plásticos.

All rights reserved.

Home

-

Privacy policy

-

Contact