Polybutylene terephthalate (PBT)

The PBT, which often receives the name of the plastics category to which it belongs - polyester - is a thermoplastic made from the transesterification reaction between DMT (dimethyl terephthalate) and 1,4 - butanediol. It is one of the most important polyester, others are

PET and

PC (the latter a linear polyester containing carbonate groups).

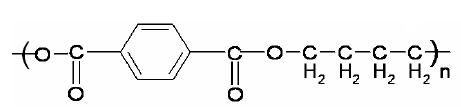

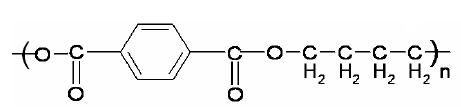

Chemical structure of PBT

Chemical structure of PBT

PBT can be reinforced with fibers and receive various types of additives commonly used in engineering plastics, it can also form blends with other polymers such as

PC,

ABS,

PTFE etc. With respect to its properties, PBT has a good chemical resistance when below 140°F (60°C) and has the advantage of rapidly to crystallize, shortening the injection molding cycle as compared with other engineering plastics, in addition to having a very good dimensional stability.

PBT finds many applications in electronics due to their stable electrical properties and in automotive industry, for its rigidity and mechanical strength. PBT is also employed in manufacturing of gears and bushings due to its low coefficient of friction and high abrasion resistance.

This polyester has excellent resistance to a wide range of chemicals at room temperature, including aliphatic hydrocarbons, gasoline, carbon tetrachloride, perchlorethylene, oils, fats, alcohols, glycols, esters, ethers and acids and diluted bases. However, PBT is attacked by strong bases.

PBT can be molded by injection or extrusion.

Features:

- High stiffness

- High impact resistance

- Good creep properties

- High thermal resistance, particularly in types reinforced with fiberglass (operating temperature up to 285°F)

- Suitable for applications requiring slip and abrasion resistance

- High dimensional stability (low coefficient of thermal expansion, low moisture absorption)

- Good electrical properties

- Good chemical resistance

- No presents "stress cracking"

- Good resistance to weathering

- Rapid crystallization, resulting in shorter cycle times

- Possibility of applying paint and metallization

- Very dependent mechanical properties of the working temperature

Applications:

It is employed in external and functional pieces in various electrical and electronic systems found in vehicles, windshield wiper arms, door handles, headlamp bezels, mirror system, connectors, components of the sunroof, sockets, switches, capacitors, plugs and so on.

Melting point:

437°F (225°C)

Glass transition (Tg):

142°F (61°C)

Bibliography:

HARPER, Charles A.; PETRIE, Edward M. Plastics Materials and Process: A Concise Encyclopedia. Hoboken: John Wiley & Sons, Inc., 2003.

WIEBECK, Hélio; HARADA, Júlio. Plásticos de Engenharia: Tecnologia e Aplicações. São Paulo: Artliber Editora, 2005.

© 2010-2025 - Tudo sobre Plásticos.

All rights reserved.

Home

-

Privacy policy

-

Contact