Poly(Methyl methacrylate) - PMMA (Acrylic)

Chemical structure of PMMA

Chemical structure of PMMA

An acrylic resin is prepared from acrylic acid or a derivative thereof. These plastics are usually based on a polymethylmethacrylate with the chemical structure shown below.

Unlike most thermoplastics, acrylic can be polymerized in a mold directly without passing through the injection process. That is, the monomer (which is liquid) has its polymerization inhibitor removed by washing, and then heated, receives an agent to initiate free radical polymerization (generally an organic peroxide) and is poured into the mold.

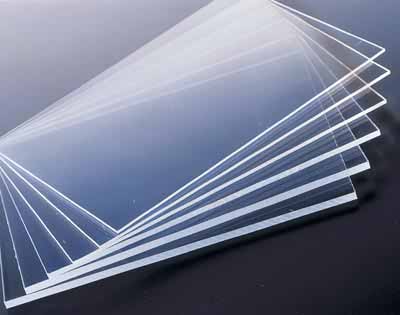

This process is most often used to produce large sheets and can not be used to manufacture materials for injection molding because of the high molecular weight acrylic produced by this technique.

For the production of acrylic for injection molding, extrusion or thermoforming, the suspension polymerization technique is used, where a solution of methyl methacrylate is dispersed in an aqueous solution and, after a period of stiring the mixture, small beads of acrylic are formed amid the liquid.

The major appeal of acrylic are their optical properties such as transparency, resistance to discoloration and loss of light transmission. Moreover, it is much cheaper than polycarbonate, an engineering plastic with very superior mechanical properties. However, it has one big disadvantage that is the low chemical resistance to solvents such as gasoline.

|

ADVANTAGES AND DISADVANTAGES

OF ACRYLIC |

| Advantages |

Disadvantages |

|

Optical clarity. Not discolour |

It is attacked by strong solvents, gasoline

and similar fluids |

| Good weather resistance |

The molded parts are subjected to high

stresses |

| Moderate strength |

|

| Good electrical characteristics |

|

| Low water absorption |

|

| Slow rate of burning |

|

| Low dimensional change in the presence of

moisture, less than 0.5% |

|

As the

polyacetal,

polypropylene,

nylon and many other thermoplastics, acrylic can be copolymerized with other monomer to improve its properties, such as with polybutadiene, improving its impact resistance - similar to what happens with HIPS (high-impact polystyrene). The acrylic-PVC blend offers high impact, hardness and good performance for thermoforming. The copolymerization of styrene with PMMA improves melt index.

Acrylic is used in applications requiring good optical properties, such as eyeglass lenses, automotive lights, windshields etc.

Applications:

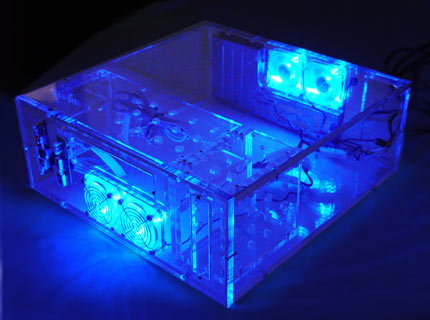

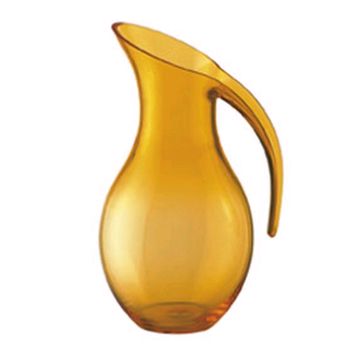

Acrylic awnings, hangers, computer case, chairs, picture frames, jars, distributor caps, shoes, lamps for car, sheets, lenses, billets etc.

Bibliography:

HARPER, Charles A.; PETRIE, Edward M. Plastics Materials and Process: A Concise Encyclopedia. Hoboken: John Wiley & Sons, Inc., 2003.

WIEBECK, Hélio; HARADA, Júlio. Plásticos de Engenharia: Tecnologia e Aplicações. São Paulo: Artliber Editora, 2005.

© 2010-2024 - Tudo sobre Plásticos.

All rights reserved.

Home

-

Privacy policy

-

Contact